STEP 2: Testing The Fuel Pump's Pressure

Once you have verified that the ignition system is not behind the engine no-start problem, your next step is to check the fuel pump.

As you already know, the electric fuel pump in your Ford Ranger is located in the fuel tank and has the task of supplying fuel to the fuel injectors at a certain pressure.

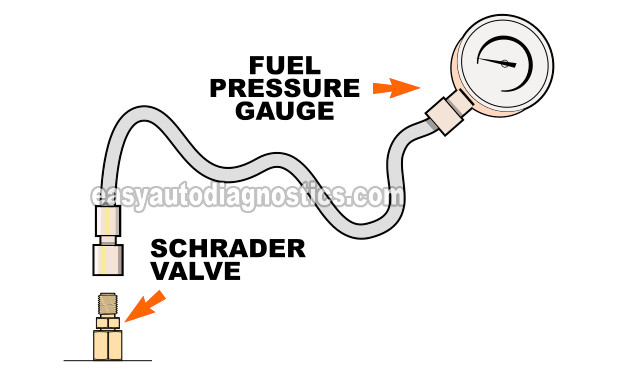

You and I can connect a fuel pressure gauge to the fuel system's Schrader valve and check the fuel pump pressure and quickly determine if the fuel pump is functioning properly or has failed.

The fuel pressure test and fuel pressure specifications can be found here:

- How To Test The Fuel Pump (1990-1994 2.3L Ford Ranger).

- How To Test The Fuel Pump (1995-1997 2.3L Ford Ranger).

The fuel system is NOT causing the no-start problem if:

- Fuel pressure is within specification.

If the fuel pressure gauge registers the indicated fuel pressure specification, then you can confidently conclude that the fuel pump is working and delivering enough fuel to the fuel injectors.

You can also conclude that the fuel pump is not behind the engine's no-start problem.

The next step is to check for a broken timing belt. Go to: STEP 3: Checking For A Broken Timing Belt.

The fuel system IS THE CAUSE of the no-start problem if:

- Fuel pressure is 0 PSI (or anything below the fuel pressure specification).

The components that can cause a 0 PSI fuel pressure problem are:

- A bad fuel pump.

- A tripped fuel pump inertia switch.

- A bad fuel pump relay.

- A bad fuel pressure regulator.

The components that can cause a low fuel pressure problem are:

- A bad fuel pump.

- A bad fuel pressure regulator.

STEP 3: Checking For A Broken Timing Belt

The 2.3L engine in your Ford Ranger is equipped with a timing belt that needs to be replaced at certain mileage intervals.

If the timing belt is not replaced within the prescribed mileage interval, it will break while the engine is running.

If the timing belt breaks, the engine will not start because the crankshaft sprocket can no longer turn the camshaft sprocket to open and close intake and exhaust valves.

A broken timing belt is NOT causing the no-start problem if:

- The timing belt is in good condition.

- The timing belt is not missing any teeth.

- The timing belt is keeping the camshaft and crankshaft sprockets synchronized.

Your next test is to check for a blown head gasket. Go to: STEP 4: Checking For A Blown Head Gasket.

A broken timing belt IS THE CAUSE of the no-start problem if:

- The timing belt is broken.

- The timing belt is missing teeth.

STEP 4: Checking For A Blown Head Gasket

Head gasket failure due to engine overheating is another common cause of an engine no-start problem.

Testing for a blown head gasket is not difficult and the following tutorial will guide you through the four tests you can perform:

A blown head gasket is NOT causing the no-start problem if:

- The engine oil has a normal color (in other words, it doesn't have a milky-white color).

- The coolant in the radiator remains undisturbed when cranking the engine (with the radiator open).

- The engine passed a block test.

Your next test is to check the engine's compression. Go to: STEP 5: Making Sure The Engine Has Good Compression.

A blown head gasket IS THE CAUSE of the no-start problem if:

- The engine oil has a milky-white color (like coffee with too much creamer).

- - or -

- The coolant in the radiator shot out when cranking the engine (with the radiator open).

- - or -

- The engine failed a block test.

STEP 5: Making Sure The Engine Has Good Compression

The four cylinders must produce enough compression to ignite the air/fuel mixture within them or the engine will not start.

An engine compression test is the test you'll need to perform to see if the cylinders are producing compression.

The following tutorial explains how to perform an engine compression test and interpret the results:

An engine compression problem is NOT causing the no-start problem if:

- The compression of each cylinder is above 120 PSI.

An engine compression problem IS THE CAUSE of the no-start problem if:

- 2 or more cylinders have 0 PSI compression.

- - or -

- All cylinders have 0 PSI compression.

No-Start Troubleshooting Summary

Troubleshooting an engine no-start problem boils down to a process of elimination.

This process of elimination involves performing specific tests to determine which component does not provide:

- Spark.

- Fuel.

- Air (compression).

The cool thing about performing the component tests is that you save yourself the frustration and money of replacing components that don't solve the problem.

More 2.3L Ford Ranger Tutorials

A full list of 2.3L Ford Ranger and Mazda B2300 tutorials can be found here:

Here's a sample of the tutorials you'll find:

- How To Test The Throttle Position Sensor (2.3L Ranger, Mustang, B2300).

- How To Test The Ignition Module And Crank Sensor (2.3L Ranger, Mustang, B2300).

- How To Test For A Blown Head Gasket (2.3L Ranger, Mustang, B2300).

- Testing The Blower Resistor (1995-1997 2.3L Ford Ranger).

If this info saved the day, buy me a beer!