TEST 2: Testing The Power Circuit

The very first thing that we'll do is check that the MAF sensor is receiving 12 Volts.

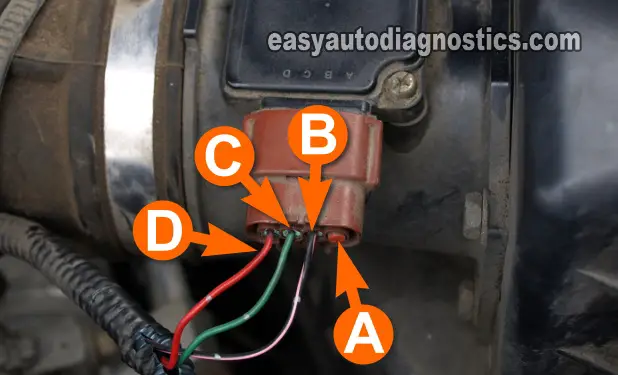

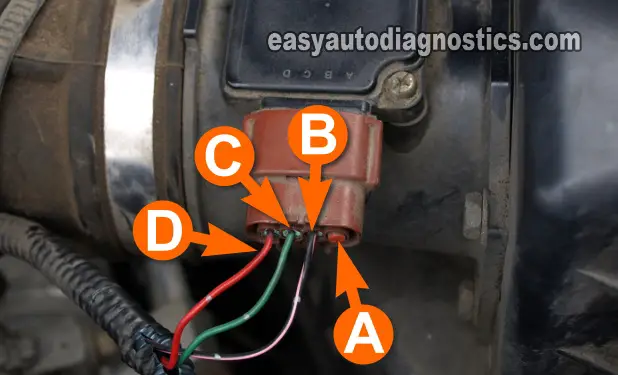

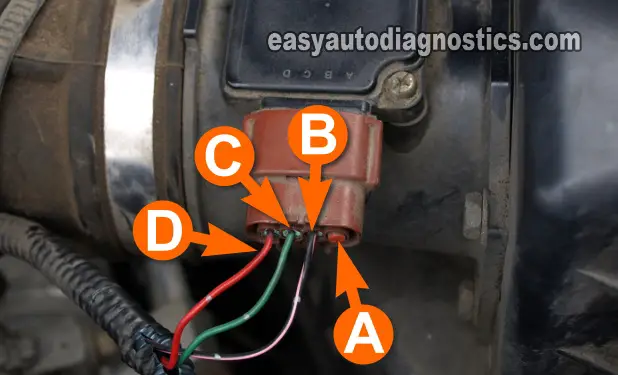

The wire that feeds this power to the MAF sensor is the wire identified with the letter B in the photo above.

The procedure I recommend for you to use (to accomplish all of the tests below) is to use a back-probe or a wire piercing probe for all of your tests. To see an example of a wire piercing probe, check out this link: Wire Piercing Probe. DO NOT insert anything into the female terminal of the connector.

Whatever method you use, the key here is not to damage the female terminal or the wire. Again, be careful. Use common sense and take all necessary safety precautions.

OK, these are the test steps:

- 1

Put the multimeter in Volts DC mode.

- 2

Disconnect the MAF sensor from its connector.

- 3

Gently probe the female terminal of the connector that connects to the wire labeled with the letter B with the red multimeter test lead.

- 4

Connect the black multimeter test lead to the battery negative (-) terminal.

- 5

Turn key ON with the engine OFF.

- 6

Your multimeter should register 10 to 12 Volts DC.

You should see 12 Volts on the multimeter. Do you have 12 Volts?

CASE 1: The multimeter registered 12 Volts. All is good in the neighborhood. The next step is to make sure that the MAF sensor is getting Ground. Go to: TEST 3: Testing The Ground Circuit.

CASE 2: The multimeter DID NOT register 12 Volts. The MAF sensor is not the problem. Without this voltage the MAF sensor will not work.

The next step is to find out why this power is missing and restore it.

TEST 3: Testing The Ground Circuit

In the previous test we checked that the sensor was receiving 12 Volts. Now we'll check that the MAF sensor is getting a good Ground. This Ground is provided by the ECM internally.

Be careful and take extreme care not to short-circuit this wire to Ground or power as you're probing it.

You can test this circuit with the connector connected to MAF sensor or not.

- 1

Put the multimeter in Volts DC mode.

- 2

Disconnect the MAF sensor from its connector.

- 3

Gently probe the female terminal of the connector that connects to the wire labeled with the letter C with the black multimeter test lead.

- 4

Connect the red multimeter test lead to the battery positive (+) terminal.

- 5

Turn key ON with the engine OFF.

- 6

Your multimeter should register 10 to 12 Volts DC.

You should see a voltage of 12 Volts. Do you have that?

CASE 1: The multimeter registered 12 Volts. All is still good in the neighborhood. The next step is to make sure that the MAF sensor is producing a signal. For this test go to: Test 4: Testing The MAF Signal.

CASE 2: The multimeter DID NOT register 12 Volts. The MAF sensor is not the problem. Without a Ground in this circuit, the MAF sensor will not work.

Although it's beyond the scope of this tutorial, your next step is to find out why this Ground is missing and restore it. This will get the MAF sensor back to work.

TEST 4: Testing The MAF Signal

Now that the basics have been checked, we'll check the MAF signal coming out of the sensor and going to the ECM. Here's a little background information to help you understand what you'll be doing in this test step.

In a nutshell, the MAF sensor measures the amount of air the engine is breathing and converts this measurement into a DC voltage signal the fuel injection computer can use to calculate fuel injection.

Specifically: At idle, when the engine is running at 800 RPMs, it needs less air than when you're revving it up to 2,700 RPMs. Naturally, the MAF sensor's voltage signal will be lower at idle and higher when you're pushing more RPMs.

The important thing to know when verifying the MAF signal is not to look for a specific MAF signal voltage reading a specific RPM but to confirm its voltage output increases/decreases as you accelerate/decelerate the engine.

The two most common results you'll get from a bad mass airflow sensor (MAF) sensor. are:

- The voltage signal is stuck in one value regardless of engine RPM.

- Erratic voltages that don't correspond to the amount of air the engine is breathing as you accelerate or decelerate the engine.

In case you're wondering, the working DC Voltage range of the MAF signal is between 0.5 and 4.5 Volts. At idle the average voltage will be abut 0.9 to 1.6 Volts depending on engine idle conditions. At around 2500 RPMs, you should a voltage of 1.7 to 2.3 Volts DC.

Start the engine and let it reach it's normal operating temperature. You'll be using the voltage reading you will obtain at idle as a base to diagnose the MAF sensor.

IMPORTANT: The MAF sensor must be connected to its connector to perform this test. You'll need to use a back-probe on the connector or a wire-piercing probe on the wire to access the MAF signal within the wire. You can see an example of this tool and where to buy it here: Wire Piercing Probe.

There are the test steps:

- 1

Connect the red multimeter test lead to the wire labeled with the letter D (see the photo above).

- 2

Put the multimeter in Volts DC mode.

- 3

Connect the black multimeter lead to the battery negative (-) terminal.

- 4

Start the already warmed up engine.

- 5

Note the Volts reading on your multimeter at idle.

This reading may be stable (with only small fluctuations) or unstable with very extreme fluctuations. No matter what the instability in the reading, this will be your base reading. - 6

Accelerate the engine as you watch the multimeter's voltage readings.

The voltage should increase as you rev up the engine. - 7

Decelerate the engine.

The voltage should decrease as you decelerate the engine. - 8

Repeat this revving up/down of the engine as you observe the voltage output.

- 9

The voltage output should increase/decrease as you accelerate/decelerate the engine.

Did the signal rise smoothly with each increase in engine acceleration and stay steady at idle?

CASE 1: The multimeter registered the indicated voltage. The MAF sensor is functioning correctly.

Here's why: If the MAF sensor were defective, your multimeter would have registered a voltage value that would've stayed stuck at one number no matter how much you revved up the engine.

CASE 2: The multimeter DID NOT register the indicated voltage. The MAF sensor is defective. Replace MAF sensor.

More Nissan 3.3L V6 Tutorials

If this tutorial was helpful, check out the others I've written for the 3.3L V6 equipped Nissan vehicles. You can find a complete list of tutorials here: Nissan 3.3L Index Of Articles.

Here's a sample of the tutorials you'll find there:

- How To Test The Camshaft Position Sensor (3.3L V6 Frontier, Quest, Pathfinder, Xterra) .

- Power Transistor Test And Ignition Coil Test 3.3L Nissan (1996-2004).

- Ignition System Wiring Diagram (1999-2004 3.3L Frontier And Xterra).

- How To Test For A Blown Head Gasket (3.3L V6 Frontier, Pathfinder, Xterra).

If this info saved the day, buy me a beer!