In this guide, I'm gonna give you a complete overview of how the fuel pump driver module (FPDM), PCM, fuel pump, and all the related signals work together to manage fuel delivery on 2004–2010 Ford F-150, F-250, and F-350 pickups with the 4.6L or 5.4L V8.

I'll explain how the system behaves under normal conditions, what each signal does, and how it all connects back to controlling the fuel pump's pressure output.

Once you've got a handle on how it's supposed to operate, you'll be way better equipped to figure out what's wrong when things go sideways with this returnless fuel system setup.

Contents of this tutorial:

- What Does the Fuel Pump Driver Module Do?

- Fuel Pump Output Control Basics.

- Fuel Pump Control (FPC) Signal Essentials.

- Fuel Pump Ground (FP RTN) Signal Essentials.

- Fuel Pump Monitor (FPM) Signal Essentials.

- Fuel Rail Pressure (FRP) Sensor.

- More Fuel Pump Troubleshooting Help.

- More 4.6L, 5.4L V8 Ford F150, F250, And F350 Diagnostic Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 4.6L V8 Ford F150: 2004, 2005, 2006, 2007, 2008.

- 5.4L V8 Ford F150: 2004, 2005, 2006, 2007, 2008.

- 5.4L V8 Ford F250: 2005, 2006, 2007, 2008, 2009, 2010.

- 5.4L V8 Ford F350: 2005, 2006, 2007, 2008, 2009, 2010.

MORE FUEL PUMP DIAGNOSTIC RESOURCES: You can find fuel pump circuit wiring diagrams, related fuel pump tests, and the inertia switch tests in this section:

FUEL PUMP DRIVER MODULE (FPDM) TESTS: This tutorial is a step-by-step guide on how to test the FPDM itself:

What Does the Fuel Pump Driver Module Do?

To really understand "why" someone at Ford decided to use a fuel pump driver module (FPDM) to control the pump in the returnless fuel system on your 2004–2010 F-150, F-250, or F-350 with the 4.6L or 5.4L V8, it helps to start by looking at the older system design. Back then, the fuel system used a mechanical pressure regulator and a return line that sent unused fuel back to the tank.

Here's how those older systems worked:

- The fuel pump relay directly powered the fuel pump anytime the engine was cranking or running.

- The pump had constant Ground wired directly to it.

- It ran at full speed all the time, putting out max fuel pressure no matter what.

- A mechanical fuel pressure regulator (mounted on the fuel rail) handled excess pressure and returned it to the tank.

- That extra fuel and pressure traveled through a return line back to the tank.

It was a simple, reliable setup that worked like a charm for years. But you know what happens once the patents run out... yep, that cash cow ran dry.

Fast forward to your Ford pickup's modern setup, and we've got something a lot more complex. The returnless fuel system now relies on a fuel pump driver module (FPDM) —and unlike the old-school system, there's no return line bringing fuel back to the tank.

Here's how this newer system works:

- The fuel pump relay now powers the FPDM (not the fuel pump directly) whenever the engine is cranking or running (key in RUN or START).

- Ground is provided by the FPDM —not hardwired to the pump.

- And this Ground isn't just ON or OFF —it's pulse width modulated (PWM), which means the module adjusts the signal strength to fine-tune fuel pressure.

- Depending on what the PCM wants, the FPDM can modulate that Ground anywhere from 10% up to 100%.

- The fuel pump no longer runs at full speed all the time —it only produces the pressure the PCM requests at any given moment.

- There's an electronic fuel pressure sensor mounted on the fuel rail that constantly feeds info to the PCM. Based on that feedback, the PCM commands the FPDM to increase, decrease, or shut off pump output.

- Because the system adjusts fuel pressure electronically and on the fly, there's no need for a mechanical regulator or a return line —there's never any "extra" fuel pressure to deal with.

Now, more electronics means more control... but also more things that can fail. And when they do, your costs start stacking up. If you ask me, this system wasn't just built for better efficiency —it's also a great new revenue stream to keep the repair industry humming along.

Fuel Pump Output Control Basics

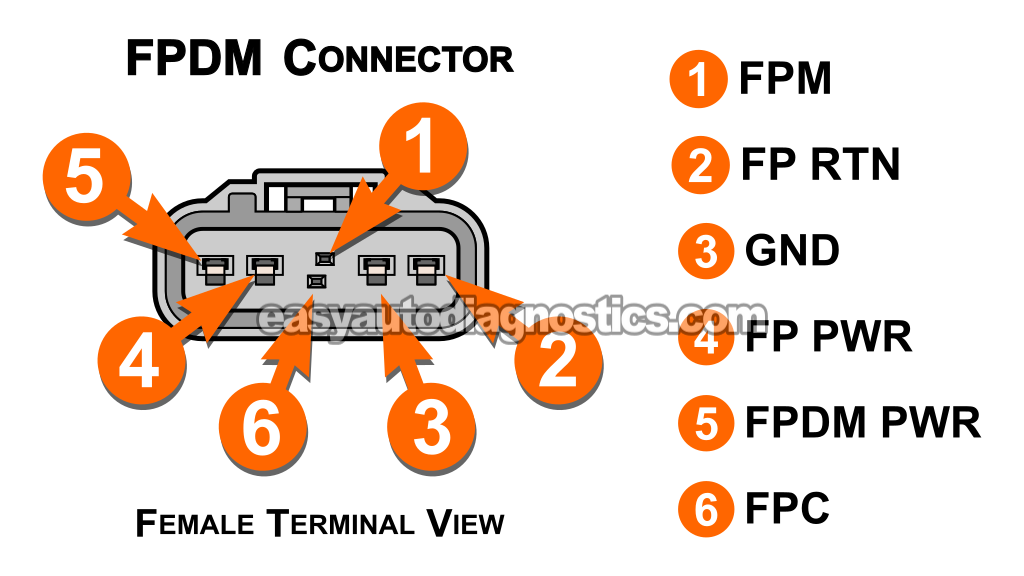

Now that you know the Fuel Pump Driver Module (also called the fuel pump control module) works as the go-between for the PCM and the fuel pump —translating the PCM's fuel delivery commands into actual pump output— let's walk through the key signals that make this system tick:

- FPDM PWR signal: When you turn the key and crank the engine, the fuel pump relay kicks in and sends battery voltage through the inertia switch. If the switch hasn't been triggered, those 12 Volts make it to the fuel pump driver module.

- PWR GND signal: A dedicated chassis Ground is always available to the FPDM through its Ground circuit.

- Fuel Pump Control (FPC) signal: This one comes from the PCM and uses a duty cycle (%) signal to tell the FPDM how fast it wants the pump to run:

- Higher duty cycle means the PCM is requesting more fuel.

- Lower duty cycle means less fuel is needed.

- FP PWR signal: This is the 12 Volt output the FPDM sends to the fuel pump after it receives instructions from the PCM via the FPC signal.

- FP RTN signal: This is the modulated Ground the FPDM provides to the fuel pump. It pulses the Ground connection ON and OFF rapidly (using PWM) to manage how much current the pump gets.

- Faster pulses mean more current to the pump —which raises fuel pressure.

- Slower pulses mean less current —which lowers pressure.

- Fuel Pump Monitor (FPM) signal: This feedback signal goes back to the PCM from the FPDM. It's duty-cycle based too, and it reports what's really happening inside the FPDM and the fuel pump circuit. You can dig into it more in: Fuel Pump Monitor (FPM) Signal Essentials

Alright, let's keep moving. In the next few sections, we'll break down those FPC, FP RTN, and FPM signals in more detail —critical know-how that's gonna help you troubleshoot FPDM and fuel pump issues with confidence.

Fuel Pump Control (FPC) Signal Essentials

Here's the key thing to know about the fuel pump control (FPC) signal: the Fuel Pump Driver Module (FPDM) is programmed to accept only specific duty cycle percentages as valid commands from the PCM.

If that signal falls outside the accepted range, the FPDM ignores it —and when that happens, the fuel pump stays off and you'll be stuck with a no-start condition.

In this section, I'm gonna walk you through what the FPDM sees as a valid command. This is critical info when you're checking the FPC signal using your multimeter.

Here's how it works: the FPDM considers any duty cycle between 5% and 50% as a valid "ON" signal from the PCM telling it to activate the fuel pump.

To break that down further:

- Closer to 5% duty cycle? That tells the FPDM the PCM wants low fuel pressure.

- Closer to 50%? That means the PCM is calling for more pressure.

- When the duty cycle hits 50%, that's full send —the PCM wants maximum fuel output from the pump.

Now, when the PCM wants to shut the pump off, it switches gears and sends a duty cycle between 70% and 80%. That range tells the FPDM: "turn it off".

If the FPC signal is outside of both of those ranges, the FPDM won't react —and that'll leave you with an engine cranking but not starting due to a lack of fuel.

NOTE: The FPC signal directly affects how much Ground the FPDM pulses to the pump. That part's coming up next in: Fuel Pump Ground (FP RTN) Signal Essentials.

Fuel Pump Ground (FP RTN) Signal Essentials

Back in the last section, I mentioned that the Fuel Pump Control (FPC) signal is directly tied to how much Ground the Fuel Pump Driver Module (FPDM) sends to the fuel pump. By now, you know the drill —the lower the FPC duty cycle, the lower the fuel pressure the PCM is calling for. The higher the duty cycle, the more pressure it wants.

Ford actually gave us a handy formula for figuring this out:

- FPC duty cycle × 2 = % of total Ground the FPDM applies to the pump.

In plain terms, the FPDM takes that FPC signal from the PCM, doubles the percentage, and uses the result to control how much Pulse Width Modulated (PWM) Ground it sends to the fuel pump. That's how it manages pump speed and pressure.

Here are a few quick examples to make sense of this:

- FPC = 50% → 50 × 2 = 100 → The FPDM sends 100% Ground → Fuel pump runs wide open at max pressure.

- FPC = 40% → 40 × 2 = 80 → The FPDM sends 80% Ground → Pump slows down, pressure drops.

- FPC = 25% → 25 × 2 = 50 → The FPDM sends 50% Ground → Pump runs even slower with lower pressure output.

It's simple math, but it gives you a powerful view into what the system's doing. If your multimeter shows the FPC signal is, say, 30%, you just double it —and now you know the FPDM is supplying 60% Ground. That tells you how hard the fuel pump is working.

Fuel Pump Monitor (FPM) Signal Essentials

As I mentioned earlier, the Fuel Pump Monitor (FPM) signal acts as a feedback channel from the Fuel Pump Driver Module (FPDM) back to the PCM.

After the PCM sends out the Fuel Pump Control (FPC) signal and the FPDM activates the fuel pump (whether the pump is good or bad), the FPM signal lets the PCM know what's actually happening on the other end of that command.

Now, don't expect super detailed info from this signal. It's not giving you exact fuel pressure numbers or voltage readings. Think of it more like a basic health check, and it comes in three distinct "status codes"—each one represented by a specific duty cycle:

- 50% duty cycle: All systems are go. The FPDM received a valid FPC command and it's carrying out its job.

- Keep in mind: even if the pump itself is bad, the FPDM will still send this 50% signal if it thinks it's doing what it's supposed to.

- 25% duty cycle: The FPDM either didn't get an FPC signal from the PCM —or the one it got was invalid.

- 75% duty cycle: The FPDM found a problem in the fuel pump circuit. That could mean an open, a short, or an overcurrent condition (like a worn-out fuel pump drawing too many amps).

This signal is how the PCM keeps tabs on what's happening downstream. If the FPM feedback doesn't line up with what the PCM expects to see, you'll either get a check engine light with a trouble code —or a fuel delivery problem... or both.

Fuel Rail Pressure (FRP) Sensor

There's one more crucial component in this fuel delivery system: the Fuel Rail Pressure (FRP) sensor. Think of it as the PCM's "eyes" when it comes to monitoring real-time fuel pressure at the injector rail.

This sensor feeds constant pressure data to the PCM, which then decides how much fuel the engine needs based on current driving conditions and engine load. From there, the PCM adjusts the FPC signal duty cycle sent to the FPDM —so the fuel pump output is always on target.

This real-time feedback loop helps the system stay dialed in and delivers:

- Best possible engine performance across all driving loads.

- Improved fuel economy by avoiding wasted pump effort.

- Cleaner emissions thanks to tightly controlled fuel pressure.

With the FRP sensor signal in conjunction with the FPM feedback signal (from the FPDM), the PCM can not only manage the fuel system —it can also keep tabs on its overall health.

If something starts to go sideways (and trust me, it will) —like the FPM signal isn't lining up with what the PCM expects, or the FRP sensor reports odd or unstable pressure— you may see a trouble code pop up. Common ones include P1233, P1235, or P1237. And in some cases, the PCM might shut off the fuel pump entirely as a fail-safe.

More Fuel Pump Troubleshooting Help

FUEL PUMP PRESSURE TESTS:

FUEL PUMP DRIVER MODULE (FPDM) TESTS:

- Fuel Pump Driver Module Tests (2004-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

- Bypassing The FPDM Module (2004-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

- Safely Probing The FPDM Connector (2004-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

FUEL PUMP INERTIA SWITCH TESTS:

FUEL PUMP CIRCUIT DIAGRAMS:

F150 Pickup:

- Fuel Pump Circuit Wiring Diagram (2004 4.6L, 5.4L V8 Ford F150 Pickup).

- Fuel Pump Circuit Wiring Diagram (2005 4.6L, 5.4L V8 Ford F150 Pickup).

- Fuel Pump Circuit Wiring Diagram (2006 4.6L, 5.4L V8 Ford F150 Pickup).

- Fuel Pump Circuit Wiring Diagram (2007-2008 4.6L, 5.4L V8 Ford F150 Pickup).

F250 And F350 Pickup:

- Fuel Pump Circuit Wiring Diagram (2005-2007 5.4L V8 Ford F250 And F350 Pickup).

- Fuel Pump Circuit Wiring Diagram (2008-2010 5.4L V8 Ford F250 And F350 Pickup).

More 4.6L, 5.4L V8 Ford F150, F250, And F350 Diagnostic Tutorials

You can find a complete list of diagnostic tutorials and wiring diagrams for the 4.6L/5.4L V8 F-Series pickups in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Ford EGR Valve, EGR Vacuum Solenoid, DPFE Sensor.

- How To Test The Ford MAF Sensor (4.2L, 4.6L, 5.4L).

- How To Test The Coil-On-Plug Ignition Coils (1997-2010 4.6L, 5.4L Ford F150, F250, F350).

- How To Test The Throttle Position Sensor (1997-2004 4.6L, 5.4L Ford F150, F250).

If this info saved the day, buy me a beer!