On 2004 to 2010 Ford F-150, F-250, and F-350 pickups equipped with the 4.6L or 5.4L engine, checking the fuel pump driver module (FPDM) is one of the most important things you should do when the fuel pressure gauge shows 0 PSI during a no-start situation.

In this guide, I'm gonna walk you through a series of step-by-step tests to help you figure out if the FPDM is bad —and believe me, it's not as complicated as it might seem at first glance.

Here's what I'm gonna cover in this hands-on tutorial:

- How to check that the FPDM is getting power (VPWR) and Ground (PWRGND) at its 6-wire connector.

- How to verify both the Fuel Pump Control (FPC) and Fuel Pump Monitor (FPM) signals.

- How to confirm that the FPDM is actually powering the fuel pump.

Let's get this pot of water boiling!

Contents of this tutorial:

- Fuel Pump Driver Module Basic Checks.

- Tools Needed To Check The FPDM.

- TEST 1: Checking The FPDM PWR (12 Volts) Circuit.

- TEST 2: Checking The PWRGND (Power Ground) Circuit.

- TEST 3: Checking Fuel Pump Activation.

- TEST 4: Checking The Fuel Pump Control (FPC) Signal.

- TEST 5: Checking The Fuel Pump Monitor (FPM) signal.

- More Fuel Pump Troubleshooting Help.

- More 4.6L, 5.4L V8 Ford F150, F250, And F350 Diagnostic Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 4.6L V8 Ford F150: 2004, 2005, 2006, 2007, 2008.

- 5.4L V8 Ford F150: 2004, 2005, 2006, 2007, 2008.

- 5.4L V8 Ford F250: 2005, 2006, 2007, 2008, 2009, 2010.

- 5.4L V8 Ford F350: 2005, 2006, 2007, 2008, 2009, 2010.

MORE FUEL PUMP DIAGNOSTIC RESOURCES: You can find fuel pump circuit wiring diagrams, related fuel pump tests, and the inertia switch tests in this section:

FPDM OPERATING THEORY: This guide explains how the FPDM works, a must read to wrap your head around how this returnless system works:

Fuel Pump Driver Module Basic Checks

Whenever you're troubleshooting a no-start issue due to a lack of fuel pressure —or chasing down a performance problem caused by low fuel pressure— on your 2004–2010 Ford F150, F250, or F350 with a 4.6L or 5.4L V8 engine, you've got to consider the fuel pump driver module (FPDM) as a possible source of the problem.

Before I walk you through a complete step-by-step diagnostic of the FPDM (which involves a couple of voltage and signal tests), there are a couple of key things we need to do first:

STEP 1 → Scan for Trouble Codes (P1233–P1237):

Grab your scan tool —it has to be able to read Ford-specific enhanced codes. What you're looking for are trouble codes tied to the fuel pump control system. The most common ones are:

- P1233: Fuel Pump Driver Module Offline or Disabled (PCM has lost communication).

- P1235: Fuel Pump Control Out Of Range (PCM can't properly command fuel pressure).

- P1237: Fuel Pump Secondary Circuit Fault (usually points to a failed FPDM).

Any of these codes means the PCM either can't see or can't control the FPDM correctly —and that's your green light to continue with in-depth FPDM tests.

NOTE: If you see a P0191 (Fuel Rail Pressure Sensor Performance), don't rule out the FPDM just yet. It might be the real cause behind erratic fuel pressure —the sensor just ends up reporting the problem.

No codes showing up? And still no fuel pump pressure output? Don't give up —some FPDM failures won't trigger a code. That's why we move on to step 2.

STEP 2 → Test Fuel Pressure Directly:

Once you've checked for FPDM-related DTCs, the next move is to connect a fuel pressure gauge and get an actual reading from the rail.

A lot of folks skip this step or rely too heavily on scan tool data —but there's no substitute for seeing exactly how much pressure the pump is making. Don't just go by the FRP (Fuel Rail Pressure) PID on the scanner (that sensor might be lying).

If you haven't done a direct fuel pressure test before, check out this walkthrough to get you started:

IMPORTANT: Even though this tutorial focuses mainly on diagnosing a no-start caused by a dead fuel pump or bad FPDM, the tests —especially the voltage drop check in TEST 2 —can also help you diagnose driveability issues tied to low pressure fuel delivery.

Tools Needed To Check The FPDM

The number one tool you're gonna need for this job is a multimeter that can read duty cycle %. Why? Because the PCM doesn't send a simple ON/OFF signal to the fuel pump driver module —it sends a Duty cycle percentage signal called the FPC signal (Fuel Pump Control).

If we want to test the FPDM properly, we've got to measure that FPC command signal and compare it to what the manual says is normal. Just as important —the FPDM responds with a return signal back to the PCM, and that's also in the form of a duty cycle %.

A multimeter that only measures frequency (in Hertz) isn't gonna cut it. What you're looking for is a meter that specifically displays duty cycle %. If you've already got one in your toolbox, great —you're good to go. If not, here's the one I own and use on these kinds of jobs:

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

Besides that, there are a few other tools you'll want to have handy:

- Wire piercing probes.

- These wire piercing probes are the ideal back probe for the FPDM tests: Straight Pins T-Pins Stainless Steel (Amazon affiliate link).

- For more info, see: Safely Probing The FPDM Connector (2004-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

- Battery jump start cable: We'll use a jump start cable to extend the reach of the multimeter test lead to the battery negative (-) post in TEST 2.

You're gonna need a wiring diagram of the FPDM circuits, and I've got you covered there too. Just head over to the More Fuel Pump Troubleshooting Help section to find the link to the specific fuel pump circuit wiring diagram for your particular F-Series pickup.

TEST 1: Checking The FPDM PWR (12 Volts) Circuit

Depending on the year of your specific F-150, F-250, or F-350, the wire delivering power from the inertia switch to the FPDM will be one of the following:

- White (WHT).

- Pink with black stripe (PNK/BLK).

- Violet with white stripe (VIO/WHT).

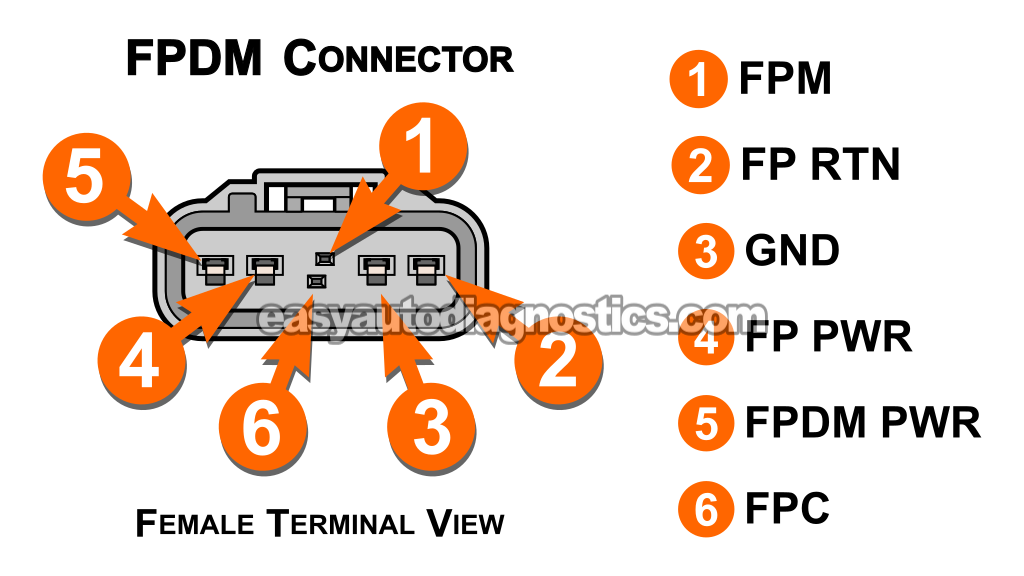

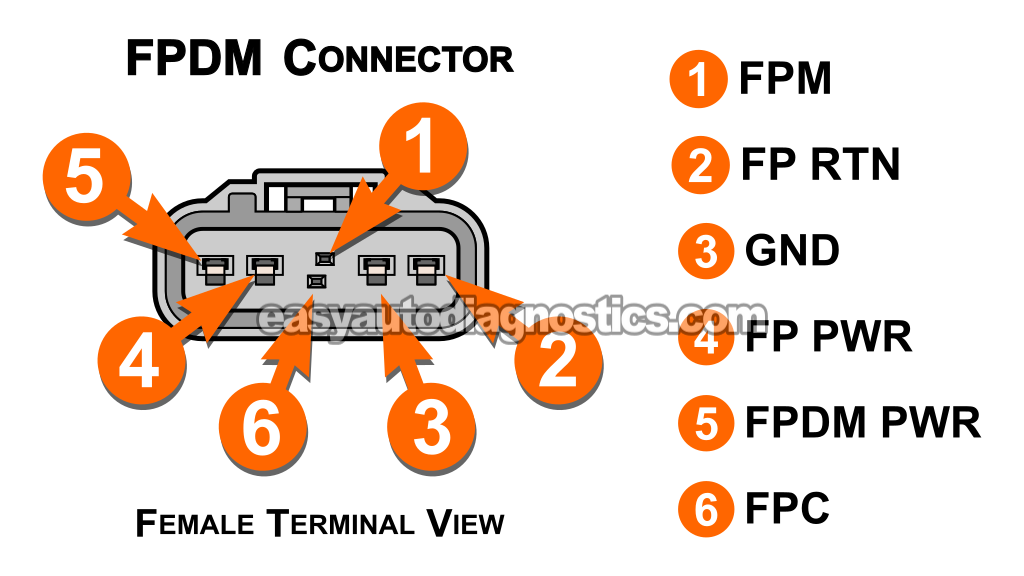

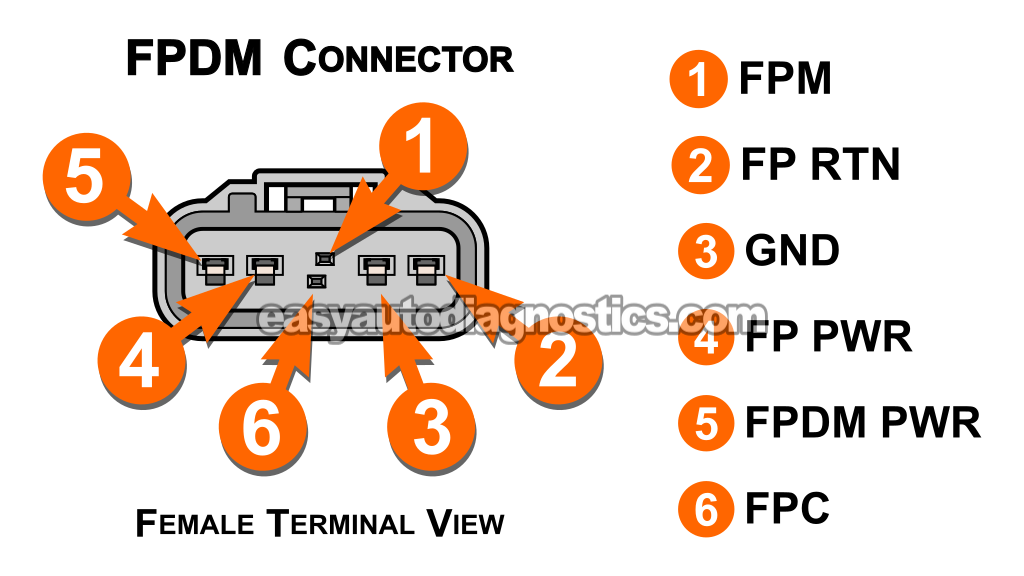

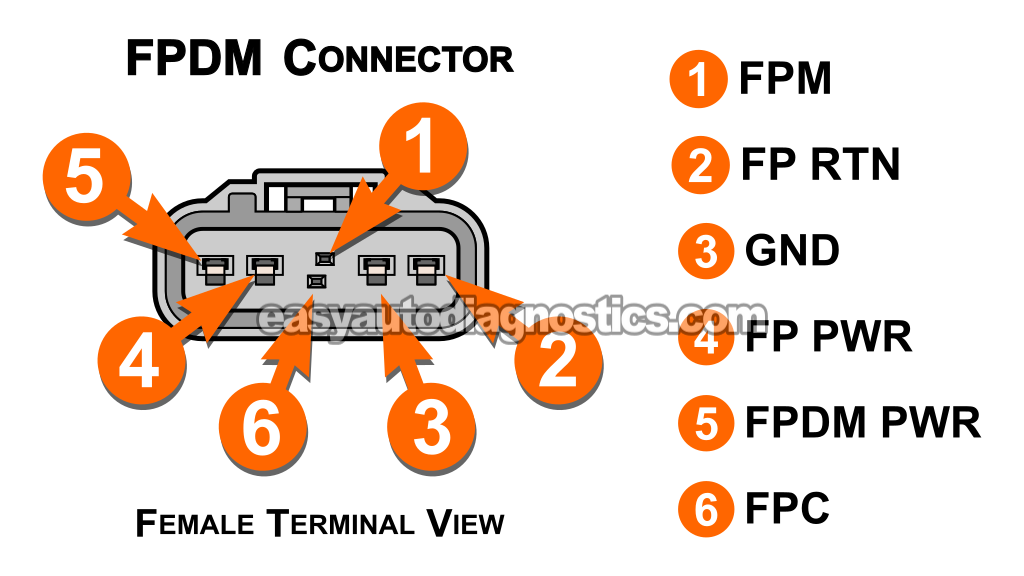

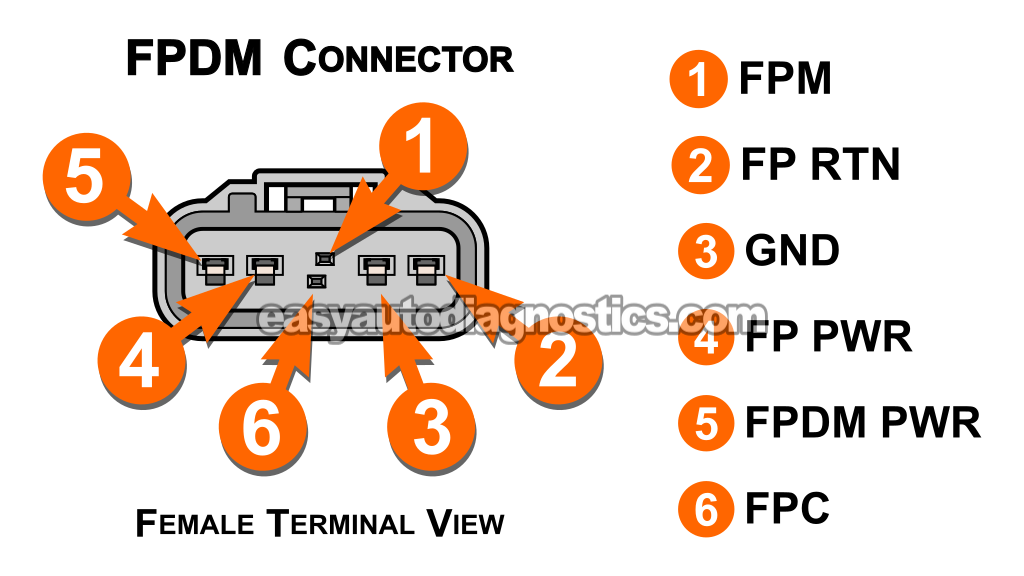

This wire connects directly to pin 5 on the FPDM's 6-wire connector and should carry full battery voltage (10 to 12 Volts) when the key is in the RUN or START position.

NOTE: Be very careful when probing the front of the FPDM 6-wire connector. Most standard multimeter test probes are too thick to safely push into the cavity of the female terminal. Make sure you don't permanently spread or damage the female terminals and cause future intermittent connection issues.

LOCATION: The Fuel Pump Driver Module (FPDM) is bolted to the driver's side rear frame cross‑member, right above the spare tire cradle. You have to lower the spare tire to see and access it.

Let's get started:

- 1

Unplug the FPDM from its 6-wire connector.

- 2

Turn the ignition key to the RUN position (engine off). This powers up the circuit from the inertia switch.

- 3

Set your multimeter to read DC voltage.

- 4

Connect the black multimeter lead to a clean metal surface on the frame or body —make sure it's free of rust and paint.

- 5

Use the red lead to gently probe terminal 5 on the connector.

- 6

You should see a reading close to battery voltage —somewhere between 10 and 12 Volts.

Let's interpret that test result:

CASE 1: You see 10–12 Volts at terminal 5. That tells you the fuel pump inertia switch is good, the fuel pump fuse hasn't blown, and power is reaching the FPDM.

That means the VPWR circuit is working. For our next test, go to: TEST 2: Checking the PWRGND (Power Ground) Circuit.

CASE 2: No voltage present at terminal 5. That's a problem. The FPDM can't work without 12 Volts —and if it's not powered, it won't turn on the fuel pump.

This could be due to a blown fuse, a tripped or defective inertia switch, or a break in the wiring between the inertia switch and the FPDM. You'll need to trace the circuit back upstream to locate the fault and get voltage restored to pin 5.

TEST 2: Checking The PWRGND (Power Ground) Circuit

For the fuel pump driver module (FPDM) to operate correctly, it needs a solid Ground connection. On your F-150, F-250, or F-350, this Ground is provided by a dedicated wire that connects directly to pin 3 of the FPDM's 6-wire harness connector.

This wire is part of the PWRGND circuit and should always have solid continuity to chassis Ground —regardless of its color.

NOTE: If you need to know the exact wire color for your specific pickup, head over to the More Fuel Pump Troubleshooting Help section and check the wiring diagram link for your truck.

Here's something important to keep in mind before we test: your truck's metal body and engine block both connect back to the battery's negative (-) terminal. But the FPDM doesn't Ground straight to the battery —it Grounds to the chassis.

And over time, those chassis Ground points can corrode —especially where the Ground straps bolt to bare metal. That corrosion builds resistance into the Ground path, and when the FPDM is under load, that resistance causes voltage drop.

When the FPDM can't get a clean Ground, it might act up —random no-starts, low fuel pressure, engine stalls— all symptoms tied to excessive voltage drop.

That's why we're not doing a basic continuity check in Ohms mode. Instead, we're gonna test this the right way —with a proper voltage drop test under real operating conditions.

IMPORTANT: The FPDM must stay connected while you run this voltage drop test.

Here's how it's done:

- 1

Plug the FPDM back into its 6-wire connector.

- 2

Set your multimeter to DC Volts mode.

- 3

Connect your red test lead to the PWRGND wire (pin 3) at the FPDM harness.

You'll need to use a piercing probe directly on the wire. - 4

Connect your black test lead to the battery's negative (-) post.

IMPORTANT: You need to hook up to the battery negative (-) post itself —not just a nearby Ground point. I usually use a jumper cable or extension wire to get the reach I need. - 5

Have a helper turn the key and crank the engine.

You want the FPDM powered and current flowing through the Ground circuit during this test. - 6

Your multimeter should read as close to 0 Volts as possible.

If you're seeing 5 Volts or more, that's a big red flag —we'll talk about that next.

Here's how to interpret what you saw on your multimeter:

CASE 1: Voltage reading is under 1 Volt. Perfect —the FPDM has a clean, low-resistance Ground path. You're good to go. Time to move on to the next test: TEST 3: Checking Fuel Pump Activation.

CASE 2: Voltage reading is 5 Volts or higher. That's too much voltage drop.

It means there's excessive resistance in the Ground path, and that'll mess with the FPDM's ability to do its job. You might see no-starts, low pressure, stalls —all kinds of fuel delivery issues.

The likely culprit is corrosion or a loose Ground connection between the FPDM and the chassis, or between the chassis and the battery negative (-) terminal. Start by cleaning and tightening all Ground contacts —battery, engine block, and body/chassis Grounds. Then run this test again.

If you've cleaned everything up and re-tested, you should now see less than 1 Volt —and with that solid Ground, the FPDM should be able to turn on the pump reliably.

TEST 3: Checking Fuel Pump Activation

Now that we've verified the FPDM is receiving both power and Ground, the next step is to find out whether it's actually doing what it's supposed to —powering up the fuel pump when the engine is cranking.

To run this test, I like to use a standard 12 Volt test light. But if you've got a multimeter instead, that works too —just set it to Volts DC. Either tool will get the job done, as long as you can see what's happening during cranking.

Here's what you need to know about the wires involved:

- The wire coming out of pin 4 is the fuel pump power feed (FP PWR).

- The wire coming out of pin 2 is the Ground feed to the pump (FP GND), controlled internally by the FPDM using PWM (pulse width modulation).

NOTE: If you need to know the exact wire color for your specific pickup, head over to the More Fuel Pump Troubleshooting Help section and check the wiring diagram link for your truck.

That Ground side isn't constant (it's not a chassis Ground) —the FPDM controls fuel pressure by pulse-width modulating the Ground on and off. During cranking, it should provide a nearly solid Ground (close to 100% duty cycle) to get the pump spinning.

We're gonna tap into both the power and Ground wires to see if the FPDM is completing the circuit and sending voltage to the pump.

IMPORTANT: You need to leave the FPDM plugged in during this test —we're checking operation under live conditions. To tap into the signals inside the wires, you'll need to use a wire-piercing probe. For more info, see: Safely Probing The FPDM Connector (2004-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

Let's go through the steps:

- 1

Connect the red multimeter test lead to the wire coming out of pin 4.

Use a wire-piercing probe to make the connection. - 2

Connect the black multimeter test lead to the wire coming out of pin 2.

Again, use a wire-piercing probe to make the connection. - 3

Have someone crank the engine while you watch your tool —whether it's the test light or the multimeter.

- 4

If the FPDM is doing its job:

The test light will turn on and stay lit while cranking.

If you're using a multimeter, you should see around 9 to 12 Volts.

Now, let's break down what that test result means:

CASE 1: You see the test light come on (or the multimeter reads 9–12 Volts). That's exactly what we want. This confirms four things right off the bat:

- The PCM is sending the FPC (Fuel Pump Control) signal to the FPDM.

- The FPDM is activating the FP PWR circuit and sending voltage to the pump.

- The FPDM is also completing the FP GND circuit internally.

- The FPDM is functioning correctly while under load.

So if you're still seeing 0 PSI on the fuel pressure gauge, and now, having confirmed the pump is getting both power and Ground, you can conclude the fuel pump itself is bad —it's not producing pressure and needs to be replaced.

CASE 2: The test light stays off or the multimeter shows 0 Volts during cranking. That means the FPDM isn't turning the pump on.

Double-check your test connections and repeat the test. If the reading still shows nothing, then it's time to check whether the PCM is actually telling the FPDM to energize the pump. Go to: TEST 4: Checking the Fuel Pump Control (FPC) Signal.

TEST 4: Checking The Fuel Pump Control (FPC) Signal

Up to this point, you've verified that the FPDM is getting power (TEST 1), has a strong Ground connection (TEST 2), and isn't turning the fuel pump on (TEST 3).

Now it's time to find out whether the PCM is actually telling the FPDM to activate the pump. It does that by sending the fuel pump driver module (FPDM) what's called the Fuel Pump Control (FPC) signal.

This signal isn't a steady voltage —it's a pulse-width modulated (PWM) command, measured in duty cycle (%). Basically, the PCM varies this signal to tell the FPDM exactly how much pressure it wants from the pump.

Here's how the FPC duty cycle works:

- A low duty cycle (around 5%) = the PCM is requesting lower fuel pressure.

- A higher duty cycle (closer to 50%) = the PCM wants higher fuel pressure.

- A full 50% duty cycle = the PCM is demanding maximum fuel output —full speed, full pressure.

The FPDM is constantly watching for the FPC signal and adjusts the fuel pump's pressure output accordingly —higher duty cycle equals more fuel pressure, lower duty cycle equals less.

To test the FPC signal, you'll need a multimeter that can read duty cycle percentage (%). Not all meters can do this —some only read frequency in Hertz, and that won't help in this case. If you need a good, budget-friendly option, here's the one I use and recommend:

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

IMPORTANT: The FPDM has to remain connected to its 6-wire connector while performing this test.

Here's how to run the test:

- 1

Set your multimeter to duty cycle (%) mode. Make sure it's not just in frequency (Hz) mode —we need percentage here.

- 2

Attach the black test lead to a clean, paint-free Ground on the chassis.

- 3

Back-probe the FPC signal wire at the FPDM connector:

The FPC signal wire is the one coming out of pin 6 of the FPDM connector. - 4

Have a helper crank the engine while you watch the multimeter reading.

- 5

You should see a duty cycle reading close to 50% during cranking.

NOTE: A normal duty cycle from the PCM usually falls between 5% and 50% depending on demand. During startup, it's usually hovering right around 50%.

Let's go over what that reading means:

CASE 1: You're seeing a 40–50% duty cycle during cranking. That's a solid signal —the PCM is doing its job and telling the FPDM to activate the pump. If the pump still doesn't run, and you've already:

- Verified power is reaching the FPDM (TEST 1),

- Confirmed the Ground path is clean (TEST 2), and...

- Found that the FPDM isn't powering the pump (TEST 3),

Then the module just isn't responding and that points to a failed FPDM. You'll need to replace it. But before you do, it's a smart move to check the fuel pump's amperage draw —a failing pump pulling too many amps could fry the new FPDM too.

CASE 2: There's no duty cycle reading —the meter shows 0%. That means the PCM isn't sending a Fuel Pump Control (FPC) signal to the FPDM. And if the FPDM doesn't get the command, it'll never activate the pump.

This usually means there's an open in the FPC wire —somewhere between the PCM and the FPDM. Your next step is to track down the break and get that signal path restored.

OPTIONAL: If you want to bypass the FPDM and run the pump manually for testing purposes, this guide shows you how to do it safely:

TEST 5: Checking The Fuel Pump Monitor (FPM) signal

NOTE: This is an optional test. It's here to show you how to check the FPM (Fuel Pump Monitor) signal in case you ever need to confirm that the FPDM is communicating properly with the PCM.

When the FPDM is working correctly —meaning it's receiving power, has a clean Ground, and is getting a proper command signal— it'll send a 50% duty cycle feedback signal back to the PCM through the FPM wire.

That FPM signal travels back to the PCM on the wire that exits pin 1 of the FPDM's 6-wire connector.

The job of this signal is to let the PCM know what the FPDM is seeing on the fuel pump side. Depending on the situation, the FPDM will output one of these three duty cycle values:

- 25% duty cycle: The FPDM didn't receive a valid Fuel Pump Control (FPC) signal from the PCM.

- 50% duty cycle: Everything is normal —the FPDM received the command and is doing its job. The fuel pump may be toast, but the FPDM has diagnosed itself as OK.

- 75% duty cycle: There's a problem on the fuel pump side —like an open-circuit, short, or the pump drawing too much current.

In this test, what we're looking for is any one of those signals. If you can confirm that a valid duty cycle (25%, 50%, or 75%) is being sent back, that tells you the feedback wire is alive and the FPDM is successfully reporting back to the PCM.

Alright, here's how to run the FPM signal check:

- 1

Put your multimeter in duty cycle (%) mode. If your meter doesn't support this function, you'll need one that does.

- 2

Attach the black meter lead to a clean and paint-free spot on the chassis.

You can use a piece of sandpaper to clean a spot on the frame rail (if necessary). - 3

Probe the wire coming out of pin 1 of the FPDM connector.

- 4

Have your helper crank the engine while you keep your eye on the meter.

- 5

You should see a duty cycle reading 50% if the system is working properly during cranking (assuming the engine doesn't start).

NOTE: A reading of 25% or 75% is also valid —these still indicate the FPDM is powered up and talking to the PCM.

Here's how to break down what you saw:

CASE 1: You see a 50% duty cycle. That's the expected result and means the FPDM sees no issues on its end. It's receiving a valid command and believes everything's operating normally.

- If your fuel pressure gauge still reads 0 PSI and the engine won't start, the fuel pump itself is likely the problem —especially if you confirmed in TEST 3 that the FPDM is sending both power and Ground to the pump.

- If fuel pressure is normal and the engine still doesn't start, then the issue lies elsewhere —not with the fuel system.

CASE 2: You see 25% or 75% duty cycle. That tells us the FPDM is active, but it's reporting a fault back to the PCM.

- 25% duty cycle: This usually means one of the following:

- The FPDM isn't receiving the FPC command from the PCM.

- It's receiving an invalid FPC signal (outside the 5%–50% "pump ON" range).

- It hasn't received the PCM's "turn off" command, which is normally a 70%–80% duty cycle.

- 75% duty cycle: This points to a problem between the FPDM and the fuel pump —possibly a bad pump, a short, or an open in the power or Ground wire going to the pump.

CASE 3: No signal at all —the meter reads 0%. That usually means the FPDM isn't powering up in the first place. The most common reason? A tripped inertia switch that's blocking power to the module.

If the inertia switch is fine and you've verified that power is reaching the FPDM, check the Ground side next —a corroded or loose chassis Ground can block operation.

If both power and Ground check out and you're still getting no feedback signal, then the FPDM has failed internally and needs to be replaced.

More Fuel Pump Troubleshooting Help

FUEL PUMP PRESSURE TESTS:

FUEL PUMP AMPERAGE DRAW TESTS:

FUEL PUMP DRIVER MODULE (FPDM) TESTS:

- FPDM Basic Operating Theory (2004-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

- Bypassing The FPDM Module (2004-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

- Safely Probing The FPDM Connector (2004-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

FUEL PUMP INERTIA SWITCH TESTS:

FUEL PUMP CIRCUIT WIRING DIAGRAMS:

F150:

- Fuel Pump Circuit Wiring Diagram (2004 4.6L, 5.4L V8 Ford F150 Pickup).

- Fuel Pump Circuit Wiring Diagram (2005 4.6L, 5.4L V8 Ford F150 Pickup).

- Fuel Pump Circuit Wiring Diagram (2006 4.6L, 5.4L V8 Ford F150 Pickup).

- Fuel Pump Circuit Wiring Diagram (2007-2008 4.6L, 5.4L V8 Ford F150 Pickup).

F250 And F350:

- Fuel Pump Circuit Wiring Diagram (2005-2007 5.4L V8 Ford F250 And F350 Pickup).

- Fuel Pump Circuit Wiring Diagram (2008-2010 5.4L V8 Ford F250 And F350 Pickup).

More 4.6L, 5.4L V8 Ford F150, F250, And F350 Diagnostic Tutorials

You can find a complete list of diagnostic tutorials and wiring diagrams for the 4.6L/5.4L V8 F-Series pickups in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Ford EGR Valve, EGR Vacuum Solenoid, DPFE Sensor.

- How To Test The Ford MAF Sensor (4.2L, 4.6L, 5.4L).

- How To Test The Coil-On-Plug Ignition Coils (1997-2010 4.6L, 5.4L Ford F150, F250, F350).

- How To Test The Throttle Position Sensor (1997-2004 4.6L, 5.4L Ford F150, F250).

If this info saved the day, buy me a beer!