Bypassing the fuel pump driver module (FPDM) on the 2004–2010 4.6L or 5.4L V8 Ford F-150, F-250, or F-350 is a quick and simple way to power the fuel pump directly and see if it's still working.

This is a super useful test when you're dealing with a no-start condition and think the fuel pump might be the issue (it lets you confirm whether the pump itself still runs).

In this guide, I'm gonna show you how to put together a set of custom jumper wires and walk you through the bypass process one step at a time.

I'll also link you to a full walkthrough on testing the FPDM itself —just in case you need to take your troubleshooting a little further.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 4.6L V8 Ford F150: 2004, 2005, 2006, 2007, 2008.

- 5.4L V8 Ford F150: 2004, 2005, 2006, 2007, 2008.

- 5.4L V8 Ford F250: 2005, 2006, 2007, 2008, 2009, 2010.

- 5.4L V8 Ford F350: 2005, 2006, 2007, 2008, 2009, 2010.

MORE FUEL PUMP DIAGNOSTIC RESOURCES: You can find fuel pump circuit wiring diagrams, related fuel pump tests, and the inertia switch tests in this section:

How To Make The Jumper Wires

If you're gonna bypass the FPDM safely, you're gonna need a pair of homemade jumper wires. For this job, I recommend using standard blue male spade crimp connectors.

Now here's something important to watch out for —most blue spade terminals tend to be a little too wide or thick compared to the male terminals on the actual FPDM. And if you force one in, you risk damaging the metal female terminal inside the 6-wire connector.

So, before you slide anything into the connector, double-check the width and thickness of the male spade terminal. If it looks too bulky or oversized:

- Trim the width with a wire cutter so it closely matches the shape of the FPDM's male terminal.

- Sand down the thickness with a file or a bit of sandpaper until it slides in nice and smooth (without forcing it).

The idea here is to get a snug fit that doesn't permanently stretch or damage the terminal. Inserting a spade terminal that's the wrong size/width, and that female terminal is gonna spread —which leads to loose or intermittent connections that are gonna cause all sorts of frustrating electrical issues later on.

Another important thing to keep in mind is that your jumper wires should match the wire gauge as the wires you're bridging. Don't go thinner. Use quality automotive-grade wire, and after you crimp those connectors on, give 'em a good tug to make sure the crimp is solid.

In case you're wondering if you need an inline fuse on your jumper? Nope. That's because you're not feeding power in from an outside source —you're just connecting two existing wires in the factory harness. The circuit's already protected by the fuel pump relay fuse, so your jumper doesn't need its own fuse.

Before we move on, I want to share one more thing: take your time building these jumper wires. A clean, tight connection now will save you the headache of chasing electrical gremlins later on.

Fuel Pump Driver Module Bypass Essentials

Before we jump into the actual bypass steps, I want to state what this test really does (and what it doesn't).

Bypassing the fuel pump driver module is strictly a way to check if the fuel pump itself is still operational. That's it. If the pump kicks on during the bypass, you've confirmed that it "can" run. But nothing more.

It doesn't tell us whether the FPDM is working correctly —only that power is reaching the pump through the bypass path. And sometimes, that's all you need to find out: is the pump coming on or not?

Here's the good news —testing the FPDM directly is actually a pretty easy thing to do. All you need is a multimeter that can measure duty cycle percentage (%). They're not expensive, and I've got a full write-up that shows you exactly how to run the test, step by step. You can check it out here:

Now don't get me wrong —I'm not saying you shouldn't do the bypass. Not at all. It's a solid, fast way to check pump operation, and I'm gonna walk you through how to do it safely and cleanly.

But here's a quick tech tip: for the most accurate result, hook up a fuel pressure gauge to the rail while you do the bypass. That way, you're not just relying on your ears —you'll see whether the pump's building proper pressure.

Sometimes you'll hear the pump buzzing in the tank... But if it's weak and can't hit spec pressure, you're no closer to knowing if it's good or toast. If you need help with the fuel pressure test, here's a full how-to guide:

How To Bypass The FPDM Step-By-Step

Here's how to perform the FPDM bypass test:

- Make sure the ignition key is turned OFF or completely removed from the switch.

- Disconnect the electrical connector from the FPDM.

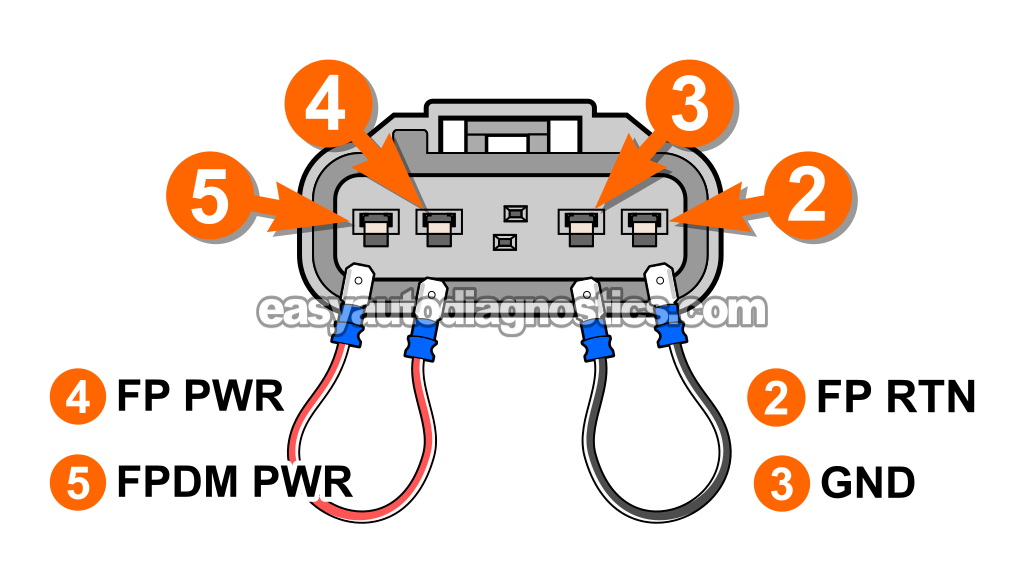

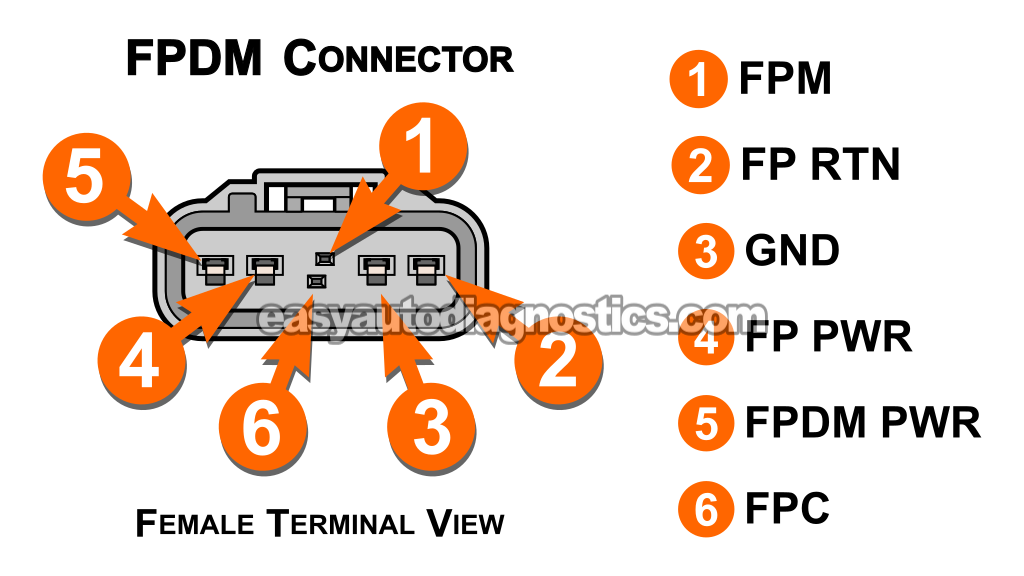

- Use your jumper wire to connect female terminals 4 and 5 —this is the power side of the fuel pump circuit.

- Terminal 4 sends power directly to the fuel pump's positive terminal (+).

- Terminal 5 receives 12 Volts when the key is in the RUN or START position. This voltage comes from the fuel pump relay, routed through the inertia switch.

- Now jumper female terminals 2 and 3 —this completes the Ground side of the pump circuit.

- Terminal 2 connects to the pump's negative terminal (–).

- Terminal 3 is tied to chassis Ground.

- Turn the key to the RUN or START position.

- The fuel pump should activate. Listen for a humming or buzzing sound coming from the tank area.

- If you've got a fuel pressure gauge hooked up, it should show the factory fuel pressure spec.

- FUEL PRESSURE SPECS: Fuel Pressure Specifications (1997-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

Here's how to read the results:

- If the pump runs and fuel pressure is within spec: The pump is good.

- If the pump runs but pressure is too low: The pump is on its way out.

- If the pump doesn't run or you're seeing 0 PSI: The pump is dead.

Just remember —this bypass is only checking the fuel pump, not the FPDM itself. If you want to test the module (and it's honestly a breeze), I've got a detailed tutorial that shows you how:

IMPORTANT: This bypass is for diagnostic purposes only. It should never be considered a permanent repair. The fuel pump is not designed to run at full speed all the time —doing so will definitely shorten its lifespan. This test is meant to verify if the pump itself can produce pressure when directly powered, nothing more.

More Fuel Pump Troubleshooting Help

FUEL PUMP PRESSURE TESTS:

FUEL PUMP DRIVER MODULE (FPDM) TESTS:

- FPDM Basic Operating Theory (2004-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

- Fuel Pump Driver Module Tests (2004-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

- Safely Probing The FPDM Connector (2004-2010 4.6L, 5.4L V8 Ford F150, F250, And F350).

FUEL PUMP AMPERAGE DRAW TEST:

FUEL PUMP INERTIA SWITCH TESTS:

FUEL PUMP CIRCUIT WIRING DIAGRAMS:

F150:

- Fuel Pump Circuit Wiring Diagram (2004 4.6L, 5.4L V8 Ford F150 Pickup).

- Fuel Pump Circuit Wiring Diagram (2005 4.6L, 5.4L V8 Ford F150 Pickup).

- Fuel Pump Circuit Wiring Diagram (2006 4.6L, 5.4L V8 Ford F150 Pickup).

- Fuel Pump Circuit Wiring Diagram (2007-2008 4.6L, 5.4L V8 Ford F150 Pickup).

F250 And F350:

- Fuel Pump Circuit Wiring Diagram (2005-2007 5.4L V8 Ford F250 And F350 Pickup).

- Fuel Pump Circuit Wiring Diagram (2008-2010 5.4L V8 Ford F250 And F350 Pickup).

More 4.6L, 5.4L V8 Ford F150, F250, And F350 Diagnostic Tutorials

You can find a complete list of diagnostic tutorials and wiring diagrams for the 4.6L/5.4L V8 F-Series pickups in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Ford EGR Valve, EGR Vacuum Solenoid, DPFE Sensor.

- How To Test The Ford MAF Sensor (4.2L, 4.6L, 5.4L).

- How To Test The Coil-On-Plug Ignition Coils (1997-2010 4.6L, 5.4L Ford F150, F250, F350).

- How To Test The Throttle Position Sensor (1997-2004 4.6L, 5.4L Ford F150, F250).

If this info saved the day, buy me a beer!